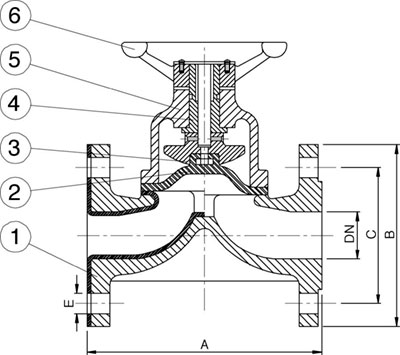

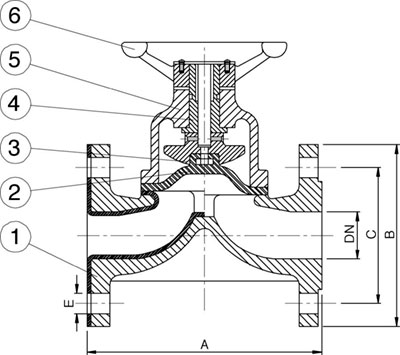

Diaphragma valve Fig. VSK | PN-10

-

WORK CONDITIONS:

FROM 1/2'' a 3'' PN-10

FROM 4'' a 6'' PN-6

FROM 8'' a 12'' PN-4Advantajes of diaphragm valves are: resisting to corrosion and abrasion, absoluta watertigh and litle cost for maintenance.

Seal is done by a membrane that´s pressed by a special pattern embólus against a curve surface seat.

Althoug it´s a vertical seat valves, the lost of pressure is minimum in due to the pattern of body and the membrane´s bend.

A lot of kinds of materials for the body covered or not, and the differents qualitys of membranes are the reason for these valves can work

even in the most difficults conditions.MATERIALS:

BODY: Cast Iron, cast iron covered with ebonite; rubber, Neopreno, halar stainless steel.

MEMBRANES: Natural rubber, Neopreno, EPDM, Butilo, Perbuna, Hypalon, Viton and Teflon. -

Nº PART MATERIAL 1 BODY INOX CF8M / IRON 6625 2 DIAPHRAGM BY REQUEST 3 DISC IRON 6625 4 NUT BRONZE 5 COVER IRON 6625 6 HANDWHEEL IRON 6625 Others materials / dimensions on request -

DIMENSIONS PANEL DN 15 20 25 32 50 65 80 100 125 150 200 250 300 A 130 150 160 180 230 295 310 350 400 480 600 730 850 B 95 105 115 140 165 185 200 220 250 285 340 395 445 C 65 75 85 100 125 145 160 180 210 240 295 350 400 N* 4 4 4 4 4 4 4 8 8 8 8 12 12 F 14 16 16 16 18 18 20 20 22 23 24 24 26 Weight (kg) 2 3 3 6 12 12 24 36 51 78 158 200 296 *Nº of holes